Description

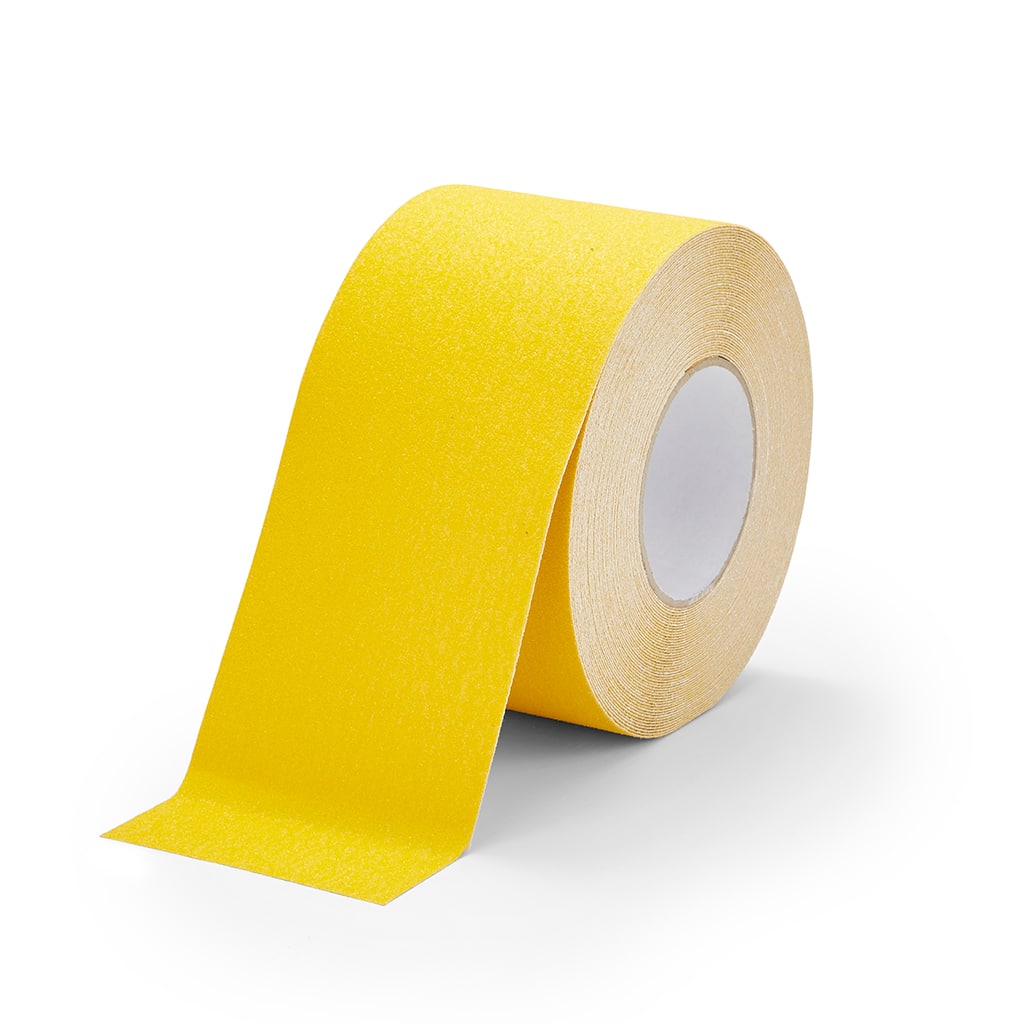

GripFactory Anti-Slip Tape Standard Yellow (100 mm x 18.3 m) is an ideal solution to temporarily provide floors and stairs with an anti-slip solution. GripFactory Anti-Slip Tape Standard Yellow can also be used as signaling. GripFactory Anti-Slip Tape Standard Yellow is available from stock.

How does it work?

GripFactory Anti-Slip Standard Tape is very easy to apply yourself. Due to the special surface structure, this anti-slip tape has an extremely high anti-slip value but is still very clean to keep.

Benefits

With GripFactory Anti-Slip Standard Tape you are assured of a long-term solution against sliding surfaces.

- Hygienic

- Easy to apply

- Removable

- Sustainable

- Cut to size yourself

- No tripping hazard

Suitable for

- Stairs

- Intermediate platforms

Technical data

- Durability: GripFactory Anti-Slip Standard Tape is impregnated with a hard ‘diamond aluminium oxide’, creating a very strong tape with a long service life.

- Adhesion: GripFactory Anti-Slip Standard Tape is treated with a special (heavy) coating, which keeps the permanent pressure sensitivity of the adhesive edge good. Because of this unique treatment of the sticky edge, the tape is excellent for use under water.

- Resistance: GripFactory Anti-Slip Standard Tape is resistant to solvents and other aggressive products.

- Temperature: GripFactory Anti-Slip Standard Tape is designed to withstand extreme temperatures (tested to-40 °C and + 80 °C).

| Topic | Result | Test method |

|---|---|---|

| Back Carrier | 0.1 mm thick foil | Calliper method |

| Total thickness applied | 0.7 mm | Calliper method |

| Type of adhesive | Solvent acrylic | n/a |

| Mineral type | Alumina | n/a |

| Adhesion to steel (g/25.4 mm2) | 1500 | PSTC-4 |

| Tensile strength (kg/25.4 mm2) | 6 | PSTC-31 |

| Tear Resistance (g) | 5600 +/- 200 | PSTC-39 |

| Peel adhesion (n/25 mm) | 23,5 | 180 degrees FINAT FTMI |

| Tensile strength (n/25 mm) | 68,0 | Lloyd, 500 N charge cell |

| Elongation at break | 25% | PSTC-31 |

| Temperature range (C) | -40 to + 80 degrees | see below |

| Maximum size of production roll | 1168 mm x 100 m | n/a |

| Resistant to water (months) | 10 | PSTC-35 |

| Resistant to chemicals (months) | 8 | PSTC-35 |

| Resistant to engine oil | Excellent | PSTC-35 |

| Lifetime (months) | 12 to 24 | PSTC-9 |

Colors

| Color | RAL Reference |

|---|---|

| Black | 9004 |

| Blue | 5000 |

| Brown | 8002 |

| Green | 6010 |

| Yellow | 1023 |

| Red | 3020 |

| Orange | 2004 |

| Fluorescent Yellow | 1016 |

| White | 9003 |

| Beige | 1000 |

| Grey | 7004 |

| Red/White | 3000 / 9016 |

| Black/Yellow | 1023 / 9017 |

LRV Test Results

| Color | LRV (average) | Range |

|---|---|---|

| Black | 3,8 | 0,16 |

| Blue | 7,7 | 0,41 |

| Brown | 6,5 | 0,49 |

| Green | 7,5 | 0,29 |

| Yellow | 48,4 | 0,59 |

| Red | 13,3 | 1,71 |

| Orange | 30,1 | 0,82 |

| Fluorescent Yellow | 103,6 | 0,71 |

| White | 87,7 | 0,29 |

| Grey | 30,3 | 0,48 |

Friction coefficient and comparison of various surfaces

| Type of surface | Dry substrate | Wet surface |

|---|---|---|

| Anti-Slip tape – Coarse | 1,33 | 1,21 |

| Anti-Slip tape – Standard | 1,29 | 1,09 |

| Anti-Slip tape – Fine | 1,37 | 1,17 |

| Ribbed rubber | 0,89 | 0,76 |

| Standard anti-slip paint | 0,69 | 0,50 |

| Painted steel | 0,77 | 0,69 |

| Structure vinyl | 0,80 | 0,64 |

| Ribbed vinyl | 0,85 | 0,72 |

Friction coefficient

| Test | Dry substrate | Wet surface | Test Standard |

|---|---|---|---|

| Pendulum | 102 TRL | 71 TRL | BS EN 13036-4L |

| DIN51130 | R13 | 97910801.001 | |

| DIN51097 | Gradient at 30 degrees C | 97910801.004 | |

| NFSI | High traction | Up to 15-07-2019 | |

The above tests were carried out in accordance with test standards. The tests were conducted at recognized independent friction control laboratories. Pendulum is a dynamic test, for static testing We also have results ASTM C 1028-96.